Anti-icing / De-icing

Aircraft are exposed to all kinds of varying conditions of the atmosphere both on the ground and while flying. They have to deal with many natural variables such as rain, snow, fog and lightning. Sometimes, even if the air temperature is not very low, icing may occur on the surface of the aircraft due to the current structure of the atmosphere. At such times, anti-icing/de-icing applications can be applied to ensure the safe flight of the aircraft.

De-icing is used to clean the ice accumulated on the outer surfaces of the aircraft. Anti-icing, on the other hand, is applied to protect the outer surface of the aircraft from this type of icing and it is a proactive and precautionary application.

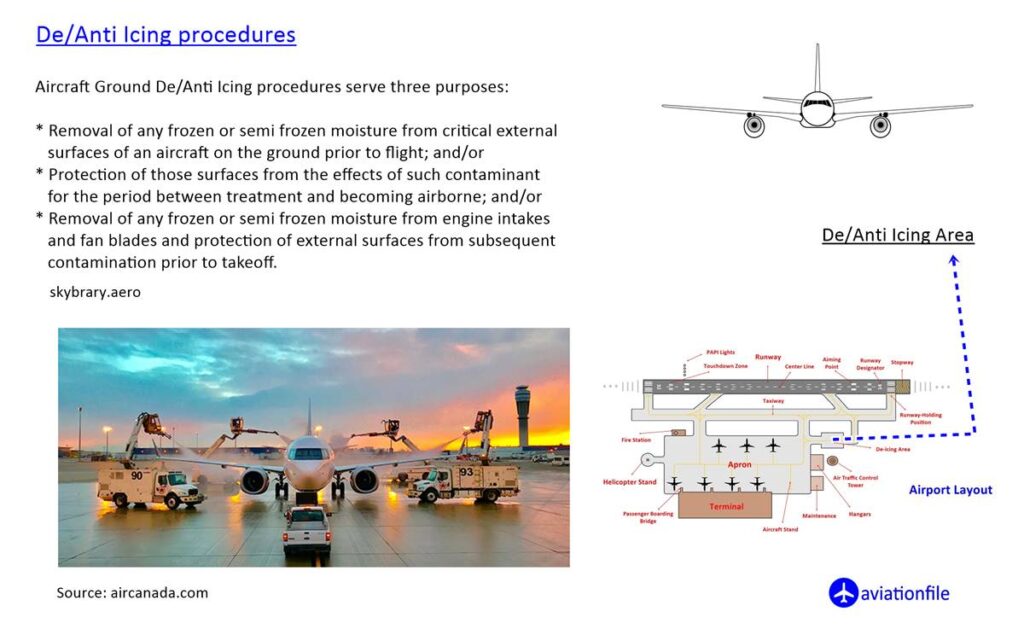

In some countries, the anti-icing/de-icing process is provided by ground handling companies. On the other hand, some companies implement these applications with the teams they have established within their own organization.

When is De-Icing / Anti-icing Applied?

Anti-icing / de-icing fluids are applied to aircraft in active frost conditions, that is, at temperatures that can cause ice and frost to form on the surfaces of the aircraft (zero degrees or dew point temperatures) and when rainfall events such as snow, slush, frozen fog are observed that can affect the aerodynamic properties of the aircraft.

Apart from these cases, there is another lesser known phenomenon known as the “Cold Soak Effect” in the literature.

The Cold Soak Effect is the case of “transparent icing” on the wings of the aircraft, which descend after flying at a high altitude for a long time and contain fuel cells at very low temperatures in the fuel cells inside the wings or load fuel at very low temperatures from the hydrant system in the apron, again as a result of the rain on their wings.

In cases where this effect is observed, de-icing can be applied to aircraft even if the air temperature is between 0 and +15 degrees.

However, de-icing is most commonly applied to airplanes that load and unload in a short time at an airport, and to airplanes that leave from the previous day to sleep.

Whether or not to receive de-icing/anti-icing service on a plane that will take off depends on the decision of the captain pilot.

In other words, if the captain does not see it necessary as a result of the examination of the pilot on a snowy day, de-icing fluid may not be sprayed on the plane.

As we mentioned at the beginning of our article, if there is snow or slush with low temperatures that cause ice formation, anti-icing fluid can also be applied after de-icing application.

The anti-icing fluid, which is green in color and has a higher viscosity than de-icing fluid, almost adheres to the applied surfaces, preventing any accumulation of snow or slush on the aircraft during the taxiing period before the aircraft takes off.

The Importance of Anti-Icing

Anti-icing practice, which is a part of winter operations at airports, is seen as relatively more critical.

Since the duration of action of the anti-icing liquid is limited, the aircraft subjected to this application must take off within a certain period of time without allowing the formation of ice again.

This protection period, which varies according to the air temperature and the liquid type, is called “Holdover Time” in the literature.

ICAO has a publication called Doc 9640 Manual of Aircraft Ground De-icing / Anti-icing Operations on this subject.

However, for Holdover Times, ICAO generally refers to the Holdover Times published by the FAA and Transport Canada, updating each year.

Where Is De-Icing Done At The Airport?

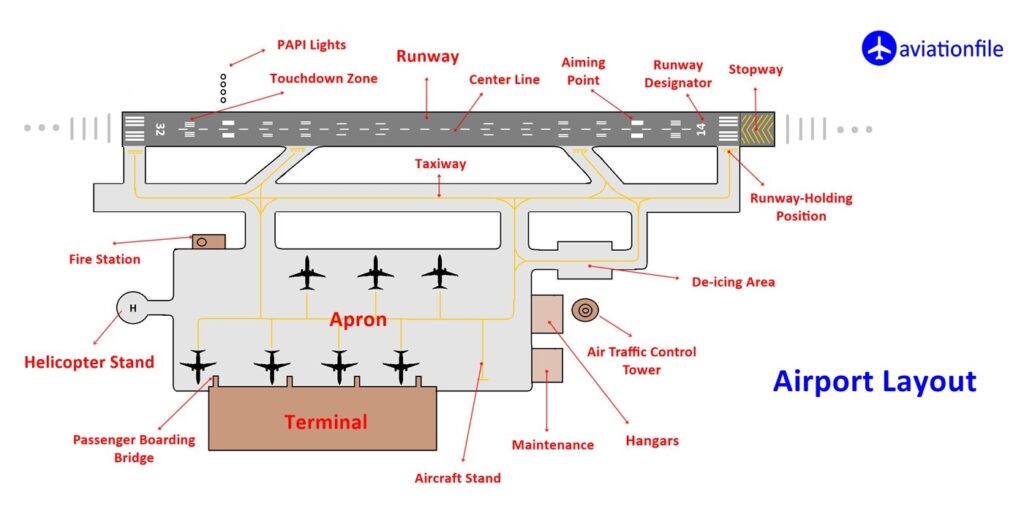

This process is done in a special area called the de-icing area, which has a different infrastructure especially in terms of drainage and collection channels.

Let us remind you that the de-icing process is carried out in bellows parking positions at some airports in the USA.

However, in many squares in Europe, de-icing operations are not allowed on the bellows for environmental reasons.

De-icing areas are tried to be kept as close to runway thresholds as possible. Because, as we mentioned above, anti-icing aircraft should take off as soon as possible.

Therefore, it is aimed to minimize the taxi time of aircraft after de-icing.

The amount of de-icing areas required at an airport is determined as a result of analyzing many different factors such as the flight schedule of the airport in question, the tariff wave structure, the number of days below zero degrees in a year.

During the de-icing / anti-icing periods, operations are arranged accordingly.

For more artciles click.