How Long Does a Commercial Aircraft Last?

Commercial aircraft represent a substantial investment, making their lifespan a critical factor for airlines and passengers alike. Understanding how long an airplane can remain in service helps in planning and operations. In this article, we delve into the typical lifespan of a commercial aircraft, examining the various factors that influence its durability and longevity, including maintenance practices, usage patterns, and technological advancements. By the end, you’ll have a clearer picture of what determines an aircraft’s service life and how airlines manage their fleets over time.

Factors Affecting the Lifespan of a Commercial Aircraft

- Maintenance and Repair: The longevity of an aircraft heavily relies on meticulous maintenance and prompt repairs. Regular inspections, routine servicing, and adherence to manufacturer guidelines ensure that an aircraft remains in optimal condition. Airlines with stringent maintenance programs often see their planes outliving the average lifespan, whereas neglect can lead to early retirement.

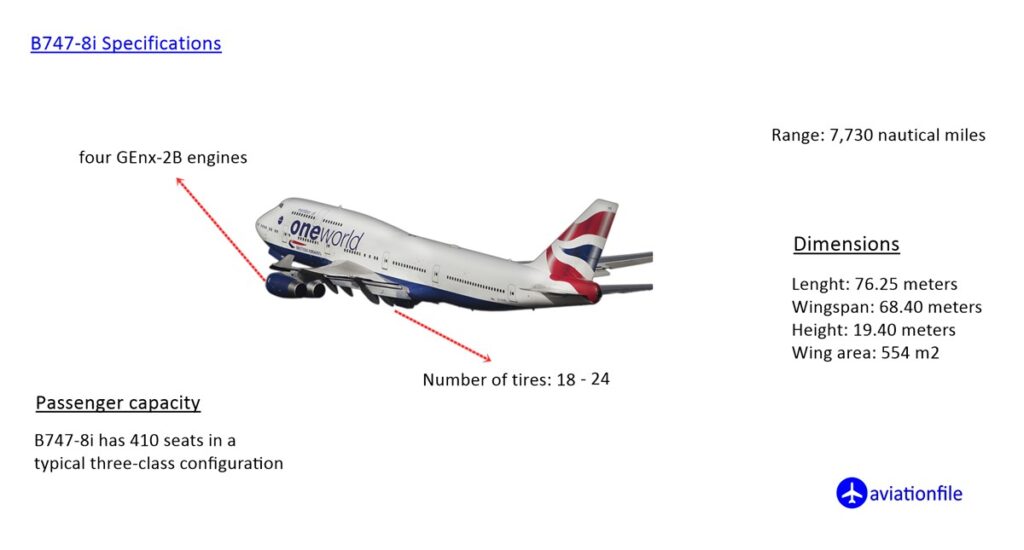

- Aircraft Type: The design and build quality of an aircraft significantly impact its lifespan. For instance, wide-body aircraft like the Boeing 747 can last up to 25 years, while narrow-body planes like the Boeing 737 generally have a 20-year lifespan. These variations arise from differences in design, materials, and intended usage.

- Usage Patterns: The operational usage of an aircraft affects its durability. Planes used for short-haul flights experience more frequent takeoffs and landings, leading to increased wear and tear compared to those used for long-haul routes. Consequently, short-haul aircraft might be retired sooner than their long-haul counterparts.

- Environmental Factors: Environmental conditions such as extreme weather, temperature fluctuations, and humidity levels can influence the lifespan of an aircraft. Exposure to harsh weather can cause exterior damage, while high humidity levels can lead to internal corrosion. Airlines operating in challenging environments must invest more in protective measures and maintenance to mitigate these effects.

- Technological Advancements: Continuous improvements in aerospace technology, including advancements in materials and engineering, contribute to extending the service life of modern aircraft. Innovations such as corrosion-resistant materials and more efficient engines help reduce the rate of wear and extend the operational lifespan.

By understanding these factors, airlines can better manage their fleets, optimize maintenance schedules, and make informed decisions about aircraft acquisitions and retirements.

Lifespan of a commercial aircraft:

The lifespan of a commercial aircraft varies depending on several factors. On average, a commercial aircraft can last between 20 to 30 years. However, some aircraft can last longer with proper maintenance and repairs.

Boeing and Airbus are two of the most prominent commercial aircraft manufacturers globally. They have estimated the lifespan of their aircraft as follows:

- Boeing estimates that their 737 series aircraft have a lifespan of 90,000 flight cycles or 55,000 flight hours, whichever comes first. The 747 series aircraft have a lifespan of around 35 years or 90,000 flight hours.

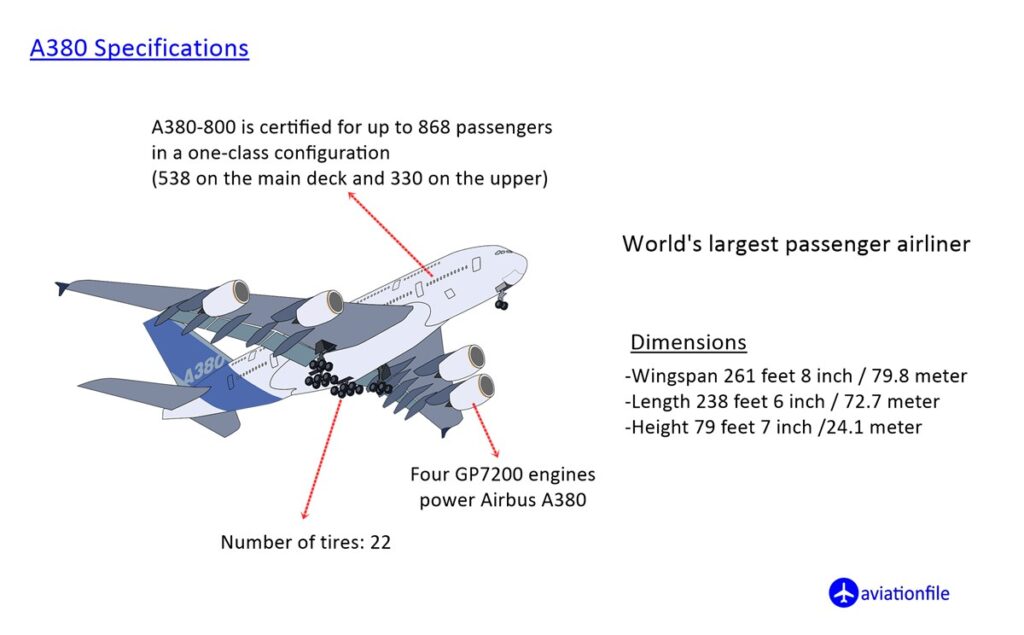

- Airbus estimates that their A320 series aircraft have a lifespan of around 60,000 flight hours or 24,000 flight cycles. The A380 series aircraft have a lifespan of around 25 years or 60,000 flight hours.

Historical Evolution of Aircraft Lifespan

The lifespan of commercial aircraft has evolved significantly over the decades, influenced by technological advancements, engineering improvements, and stricter maintenance standards. In the early days of aviation, aircraft were built with basic materials and had shorter lifespans, often limited to just a decade.

With the advent of jet engines in the 1950s and 1960s, aircraft lifespans began to increase. These engines were more reliable and required less frequent maintenance, allowing planes like the Boeing 707 and Douglas DC-8 to remain in service longer.

In the 1980s and 1990s, the introduction of advanced composite materials and improved aerodynamics further extended aircraft longevity. Planes like the Boeing 757 and Airbus A320 demonstrated the potential for 20-30 years of service with proper maintenance.

Today, modern aircraft benefit from cutting-edge technology, including corrosion-resistant materials, more efficient engines, and advanced avionics. These advancements have pushed the average lifespan of commercial aircraft to around 25-30 years, with some models exceeding 30 years of service.

This evolution reflects the industry’s ongoing commitment to enhancing safety, reliability, and efficiency, ensuring that aircraft can serve airlines and passengers for longer periods.

Future Trends in Aircraft Durability

The future of aircraft durability is set to be transformed by several emerging technologies and innovations. One key trend is the use of advanced composite materials, which are lighter and more resistant to corrosion and fatigue compared to traditional materials. These materials not only enhance durability but also improve fuel efficiency.

Another significant trend is the integration of smart maintenance systems. Utilizing predictive analytics and IoT (Internet of Things) sensors, these systems can monitor aircraft health in real-time, predicting maintenance needs before issues arise and reducing downtime.

Additive manufacturing, or 3D printing, is also revolutionizing aircraft maintenance and repairs. This technology allows for the on-demand production of complex parts, minimizing delays and costs associated with traditional manufacturing methods.

Furthermore, advancements in engine technology, such as more efficient and durable turbine designs, contribute to extending the operational life of aircraft. These engines are designed to withstand higher temperatures and stresses, leading to longer service intervals and reduced wear.

Finally, the development of sustainable aviation fuels (SAFs) and hybrid-electric propulsion systems is expected to impact aircraft longevity positively. These innovations not only reduce environmental impact but also result in less wear and tear on aircraft components, further extending their usable life.

As these trends continue to develop, the lifespan of commercial aircraft is likely to increase, offering airlines greater value and efficiency from their fleets.

Conclusion:

In conclusion, the lifespan of a commercial aircraft depends on various factors such as maintenance, aircraft type, usage, and environmental factors. With proper maintenance and repair, an aircraft can last longer than its estimated lifespan. On average, commercial aircraft can last between 20 to 30 years. However, airlines often retire their planes earlier due to economic and operational reasons.

References:

- “How long does a plane last?” Business Insider, 5 June 2018, https://www.businessinsider.com/how-long-do-airplanes-last-2018-6.

- “Lifespan of an Airplane.” Aviation Industry Corporation of China (AVIC), http://www.avic.com/en/epaper/article.aspx?id=101367.

- “Boeing 737.” Boeing, https://www.boeing.com/commercial/737ng/background.html.

- “A320 Family.” Airbus, https://www.airbus.com/aircraft/passenger-aircraft/a320-family.html.

- “A380.” Airbus, https://www.airbus.com/aircraft/passenger-aircraft/a380-family.html.

- www.aviationfile.com